The finishing machine K-44 has been designed and manufactured for the footwear repair and finishing such as shoes, boots and leather goods. The dusty residues generated by production are sucked from the nozzles then decanted by a cloth-bag specially made and deposited inside a drawer at the bottom of the machine.

The feature of this machine is the automatic filter cleaning system which, thanks to a special patented system ensures a constant and optimal filtering capacity for the benefit of the suction. The machine is able to perform essentially four types of processing inasmuch as it is equipped with:

– nr. 1 Abrasive belt mm 1440 x 50 for roughing

– nr. 1 Abrasive tampon for roughing

– Conical roughing heel breast

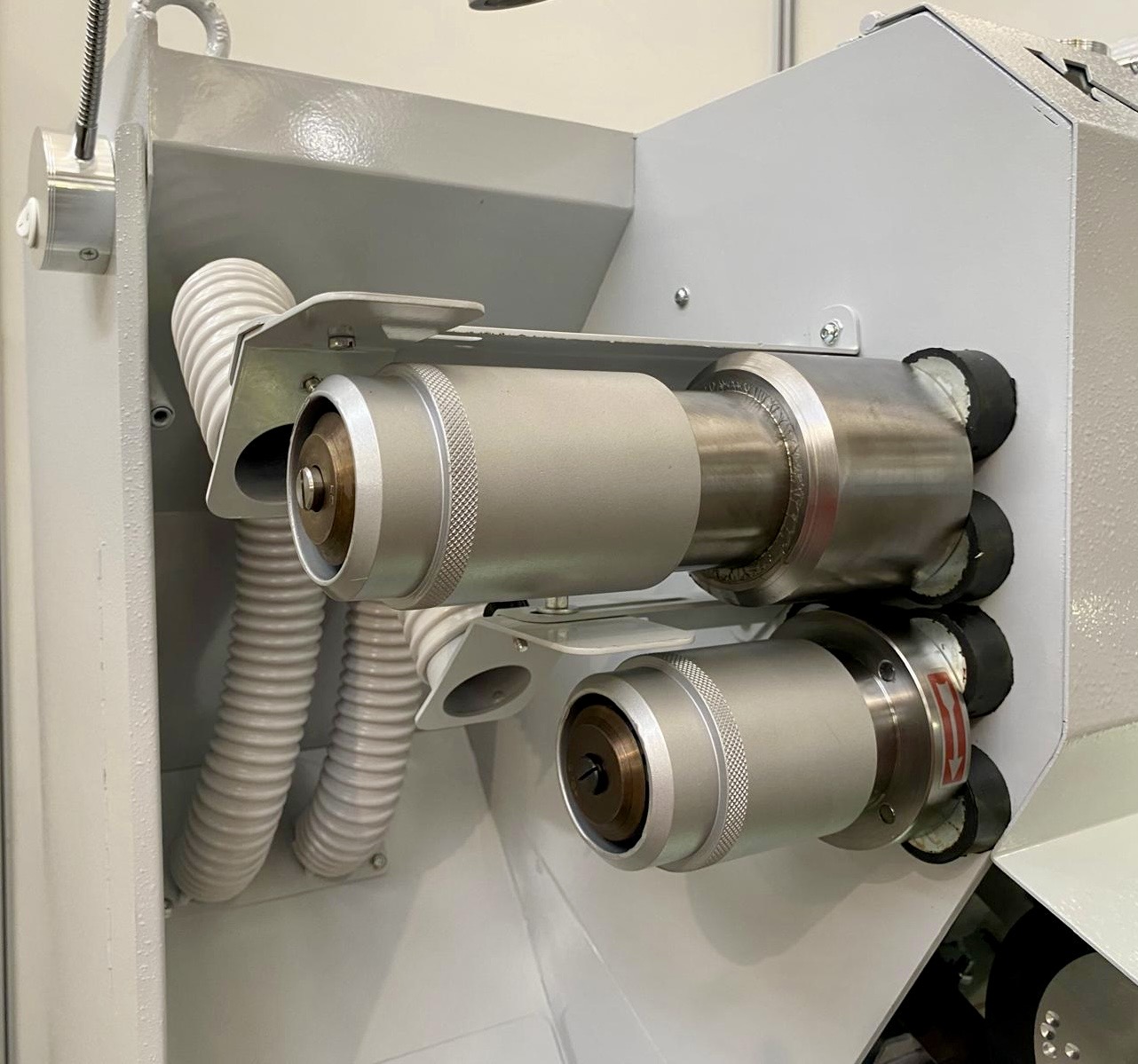

– nr. 2 Trimming cutters

– nr. 4 Brushes

– independent and tiltable naumkeag

The machine is manufactured in conformity with the CE Standards